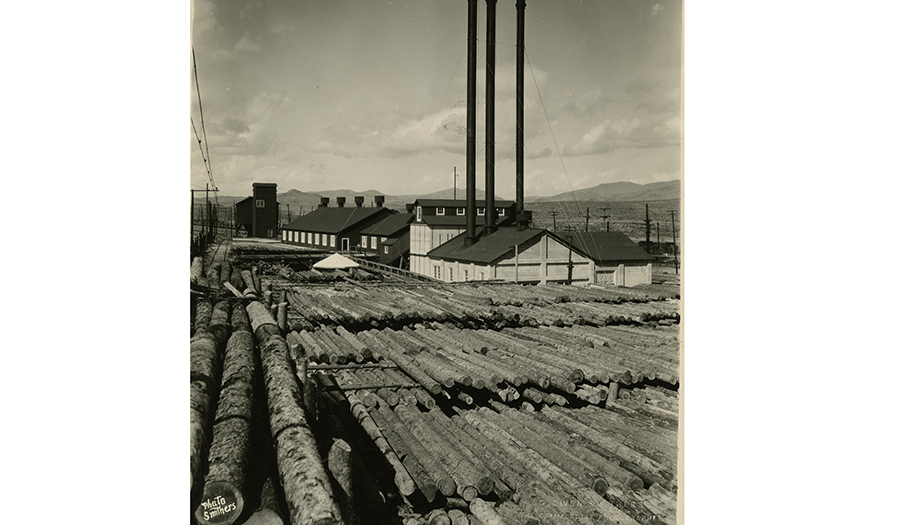

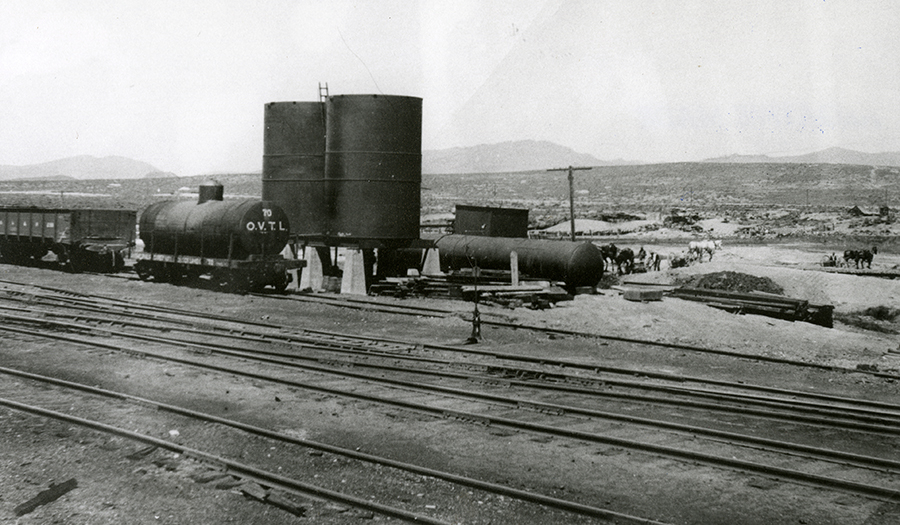

Rocker Timber Framing and Treating Plant

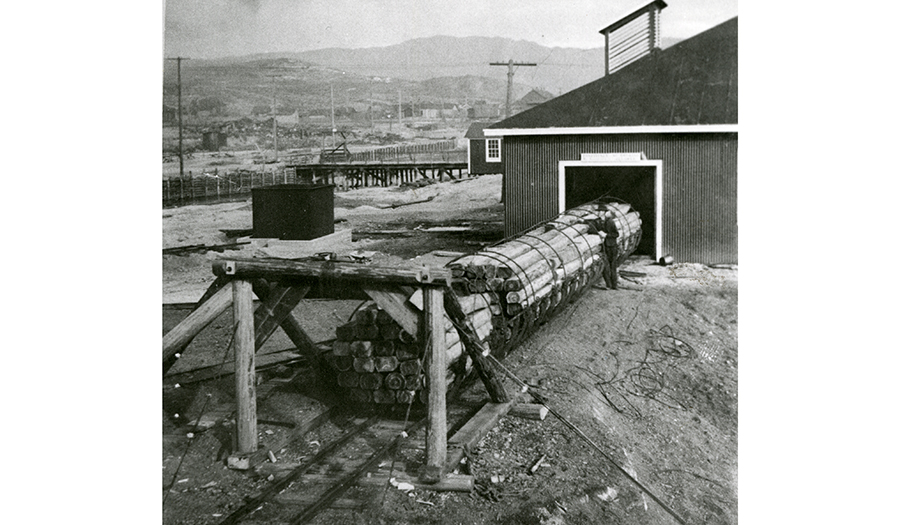

The Rocker Timber Framing and Treating Plant was constructed in 1909 and operated until the plant was closed in approximately 1957. The Anaconda Company owned and operated the site. Initially, the facility treated mining timbers with a creosote solution. Subsequently, the facility began using arsenic trioxide solutions for treatment, and this formulation became the primary treatment process up to the final days of plant operation. Rocker wood treating wastes are also mixed with contaminated tailings and other mining waste washed downstream to Rocker from mining/smelting facilities in Butte (EPA Record of Decision, 1995).

During the approximate 48-year history of plant operation, spilled process materials (arsenic trioxide powder), treated wood chip residues, and dripped or leaked process solutions (creosote and caustic heated arsenic brines) have resulted in contaminated soils throughout the plant site and significant groundwater contamination (EPA Record of Decision, 1995). The Rocker Timber Framing and Treating Plant operable unit is part of the original Silver Bow Creek Superfund Site, that was listed on the National Priorities List (NPL) on September 8, 1983.

About 1,000 cubic yards of the most highly contaminated soil (soil with arsenic concentrations exceeding 10,000 parts per million) were removed to a licensed disposal facility. The remaining soils have received different treatments/soil amendments over time, including the excavation of 48,000 cubic yards of material for treatment with iron-sulfate and lime and placement in an on-site repository. In situ treatment of soils with ferrous iron and potassium permanganate have also taken place.

A well ban prohibiting installation of wells within a quarter-mile of the site was put in place by EPA to prevent the spread of the arsenic-groundwater plume. In cooperation with EPA and DEQ, the MBMG completed a long-term aquifer test adjacent to the site where a large truck stop was being constructed to determine the potential connectivity of the deep groundwater zone and the shallow-arsenic laden groundwater plume.Results of this test were instrumental in the agencies modifying the well ban to allow the truck stop to complete the installation and use of a high-yield deep groundwater well for use at the truck stop.

Currently the MBMG provides support to the EPA and DEQ in the form of groundwater monitoring, technical review of documents, and participation in development of a conceptual site model to identify groundwater recharge and flow paths.